Common Uses for Laser Engraving Stainless Steel in Engineering Applications

Laser engraving is increasingly used in the pharmaceutical industry to provide precise, permanent, and regulatory-compliant markings on packaging, containers, and equipment. It delivers high-contrast results without affecting the integrity or safety of the material, making it ideal for sterile and controlled environments.

Other applications include:

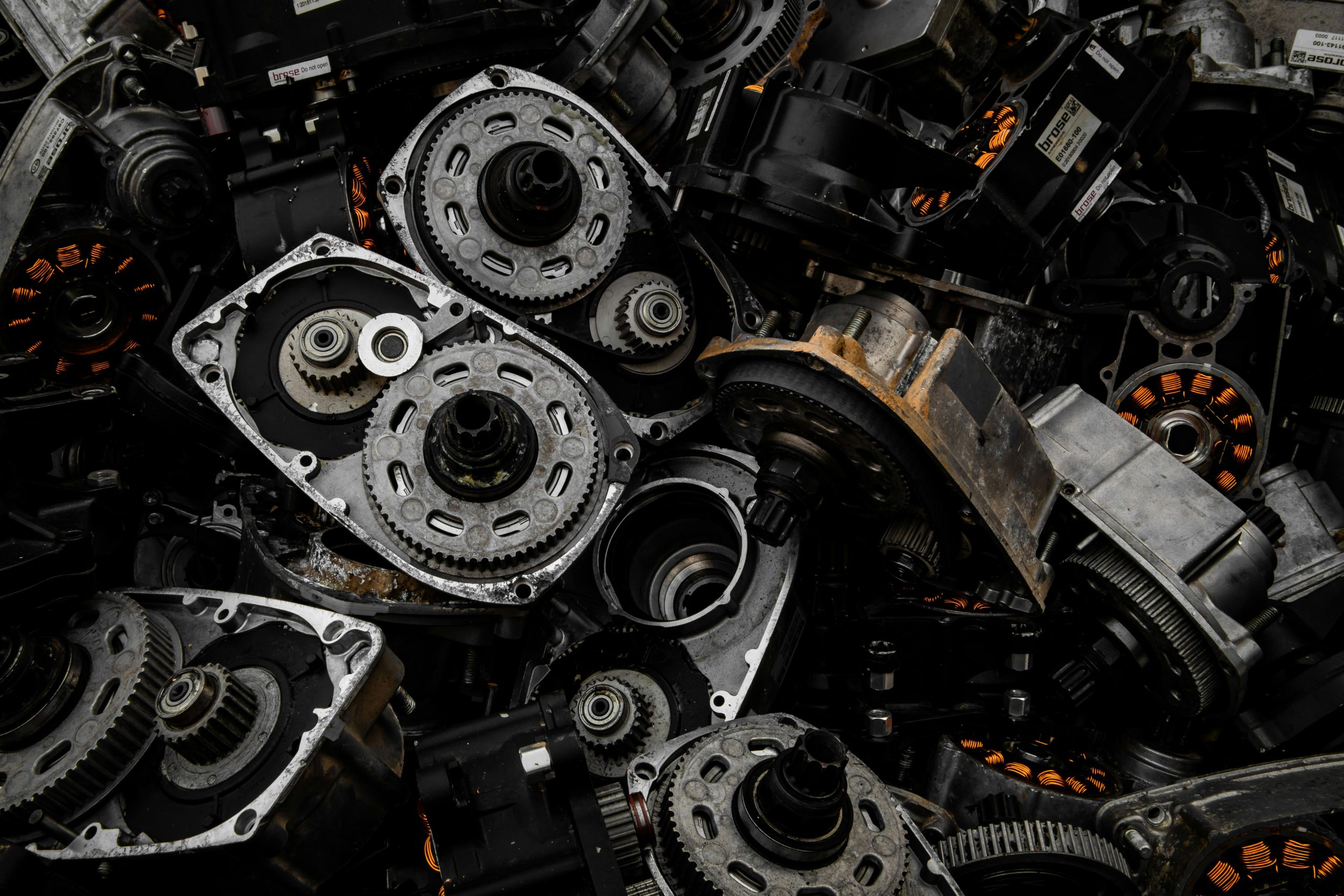

Marking Serial Numbers and Part IDs

Engineering components often require unique serial numbers or part identifiers for traceability and quality control. Laser engraving applies permanent, legible, and high-contrast markings directly onto stainless steel or other metals without affecting material performance.

Batch Codes and Production Tracking

For manufacturing and assembly lines, batch codes help track production lots and maintain quality assurance. Laser-etched markings on metal parts provide a reliable solution for traceability throughout the component’s lifecycle.

Labeling Tools, Fixtures, and Equipment

Engineering firms often reuse tools, jigs, and fixtures. Laser engraving offers a durable method to mark these items with identification numbers, ownership labels, or calibration dates. These marks withstand repeated handling, chemical exposure, and cleaning without fading.

QR Codes and Barcodes for Inventory Management

Digital inventory systems benefit from laser-engraved QR codes or barcodes on metal components and assemblies. These marks allow rapid, reliable scanning, helping firms track parts, monitor usage, and maintain accurate maintenance or production records.

Branding Logos and Technical Specifications

Laser engraving can apply company logos, model numbers, or technical details directly onto engineering components. This creates professional, permanent marks that enhance product identification, support assembly accuracy, and maintain brand consistency without adhesives or labels.

Corrosion-Resistant, Durable Marks

Laser annealing or etching produces smooth, high-contrast marks that resist wear, corrosion, and environmental exposure. Unlike traditional marking methods, laser engraving maintains material integrity while delivering markings that endure heavy-duty use, harsh chemicals, and cleaning processes.

Benefits of Laser Engraving for Engineering Firms

In engineering and manufacturing, precision, durability, and traceability go far beyond aesthetics. Components, tools, and assemblies require permanent, high-quality markings that can withstand harsh industrial environments. Laser engraving for engineering applications provides a controlled, non-contact process that delivers consistent results, offering benefits such as:

Permanent & Durable

Laser-engraved marks are designed to last for the lifetime of the component. Unlike ink-based or mechanical marking methods, laser engraving does not introduce wear or weaken the material. Marks remain legible even under heavy use, extreme temperatures, or exposure to chemicals and abrasives.

Supports Industry Standards

Laser engraving helps engineering firms comply with industry requirements for traceability, part identification, and quality control. By producing permanent, high-contrast marks, manufacturers can track components throughout production, assembly, and service cycles, streamlining audits and documentation.

Non-Contact Precision

Laser engraving does not physically touch the part, eliminating wear, scratches, or distortion. This ensures consistent mark quality across thousands of parts, even on delicate, small, or complex geometries. Non-contact processing is ideal for precision components where surface integrity is critical.

Micro-Marking Capability

Many engineering components offer limited space for identification. AZ Industrial Lasers’ systems can produce ultra-small, high-resolution markings on tight surfaces without compromising part functionality. Serial numbers, QR codes, and technical specifications can be etched clearly on miniature or curved surfaces.

Low Maintenance & No Consumables

Laser engraving eliminates the need for inks, chemicals, or abrasive tools. There are no fluids to store, clean up, or dispose of, reducing operating costs and simplifying compliance with environmental and safety regulations. Systems are engineered for long-term, reliable operation with minimal upkeep.

Versatile & Adaptable

From tools, fixtures, and machinery parts to metal and plastic components, laser engraving adapts to a wide range of engineering materials. High-contrast, corrosion-resistant markings ensure parts remain identifiable even in industrial, outdoor, or harsh chemical environments.